LYTO’S si dota di un nuovo modello di organizzazione, gestione e controllo

13/12/2014

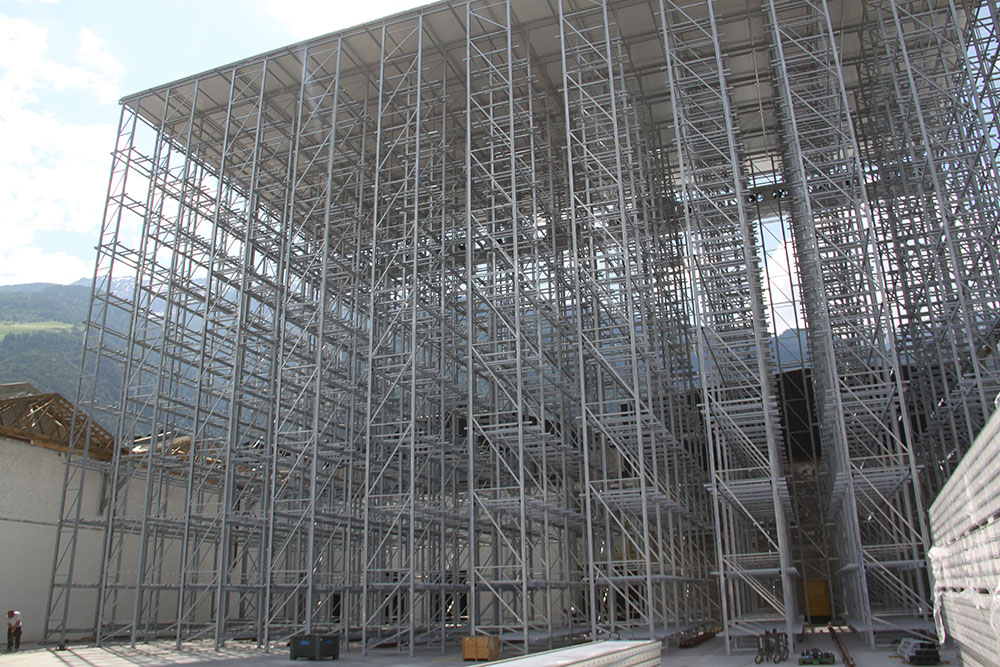

Research and development in Lyto’s: evolution of fixing systems

31/07/2016When weather conditions are extremely hard, or when the Costumers ask for an absolute guarantee on the durability of structural coating, Lyto’s can realize structures fully galvanized by immersion, according to standard UNI EN ISO 1461, which gives to the structures of the warehouse, a resistance to stress and corrosion of the highest level.

With Lyto’s hot-dip galvanizing, every structural element, after the usual mechanic processes and welding, is immerse in a pure zinc bath of 450 °C, also after the processes of degreasing, pickling and fluxing in order to make the steel uncontaminated and in order to facilitate the reaction between steel and zinc.

“So this is not the traditional galvanizing, well known in the field of metal shelving, which provides profiles obtained directly from galvanized strips, and then machined and drilled, with evident problems of protection and consequently of corrosion in the areas of cut and drilling, but it is a treatment that offers to Lyto’s customers an absolute guarantee and the highest quality.”

Once again Lyto’s demonstrates able to provide to its Customers, the most appropriate solutions.